In: Burley J, Evans J, Youngquist JA (eds) Encyclopedia of forest sciences. Ince PJ (2004) Pulping – fibre resources. In: Sixta H (ed) Handbook of paper and board. In: Tappi sizing short course, Session 1. In: Gullichsen J, Fogelholm CJ (eds) Chemical pulping – papermaking science and technology. Gullichsen J (2000) Fibre line operations. In: Dence CW, Reeve DW (eds) Bleaching chemicals: chlorine dioxide. Wiley, New York, p 271įredette MC (1996) Section 2, Chapter 2: Pulp bleaching: principles and practice. In: Grayson M (ed) Kirk-Othmer encyclopedia of chemical technology, vol 4, 4th edn. November 2002įarr JP, Smith WL, Steichen DS (1992) Bleaching agents (survey). EPA Office of Compliance Sector Notebook Project. ĮPA (2002) Profile of the pulp and paper industry, 2nd edn. ĮPA (2001b) Pulping and bleaching system NESHAP for the pulp and paper industry: a plain English description. TAPPI/CPPA, Atlanta/Montreal, p 39ĮPA (2001a) Pulp and paper combustion sources national emission standards for hazardous air pollutants: a plain English description. In: Hagemeyer RW, Manson DW (eds) Pulp and paper manufacture, vol 6. Tappi J 66(1):155–156Ĭasey JP (1983b) Mechanical and chemi-mechanical pulping: a perspective. Academic, San Diego, p 754īuck RJ (2006) Fourdrinier: principles and practices, 2006 In: TAPPI papermakers conference, Atlanta, 24–28 April 2006, Session 15, 13ppĬasey JP (1983a) Chemical pulping: a perspective. In: Scientific and technical advances in refining and mechanical pulping, 8th Pira International refining conference, Pira International, Barcelona, 28 February–March 2005īiermann CJ (1996) Handbook of pulping and papermaking, 2nd edn.

Pira International, Leatherhead, 197 ppīaker CF (2005) Advances in the practicalities of refining. Elsevier Science, Amsterdamīaker C (2000) In: Baker C (ed) Refining technology. Elsevier, Amsterdamīajpai P (2013) Recycling and deinking of recovered paper. PIRA International, Leatherhead, 166 ppīajpai P (2012) Environmentally benign approaches for pulp bleaching, 2nd edn. PIRA International, Leatherhead, 140 ppīajpai P (2008) Chemical recovery in pulp and paper making. PIRA International, Leatherhead, 159 ppīajpai P (2005) Technological developments in refining. Solutions! :28–30īajpai P (2004) Emerging technologies in sizing. Fapet Oy, Helsinki, p 135Īrppe M (2001) Mechanical pulp: has it got a future or will it be discontinued? Int Papwirtsch 10:45–50Ītkins J (2005) The forming section: beyond the fourdrinier. In: Gullichsen J, Paulapuro H (eds) Papermaking science and technology, vol 6B. STFI-Packforsk, Stockholm, 82 ppĪrpalahti O, Engdahl H, Jantti J, Kiiskila E, Liiri O, Pekkinen J, Puumalainen R, Sankala H, Vehmaan-Kreula J (2000) Chapter 14: White liquor preparation. TAPPI/CPPA, Atlanta/Montreal, p 590Īnnergren G, Lundqvist F (2008) Continuous kraft cooking: research and applications.

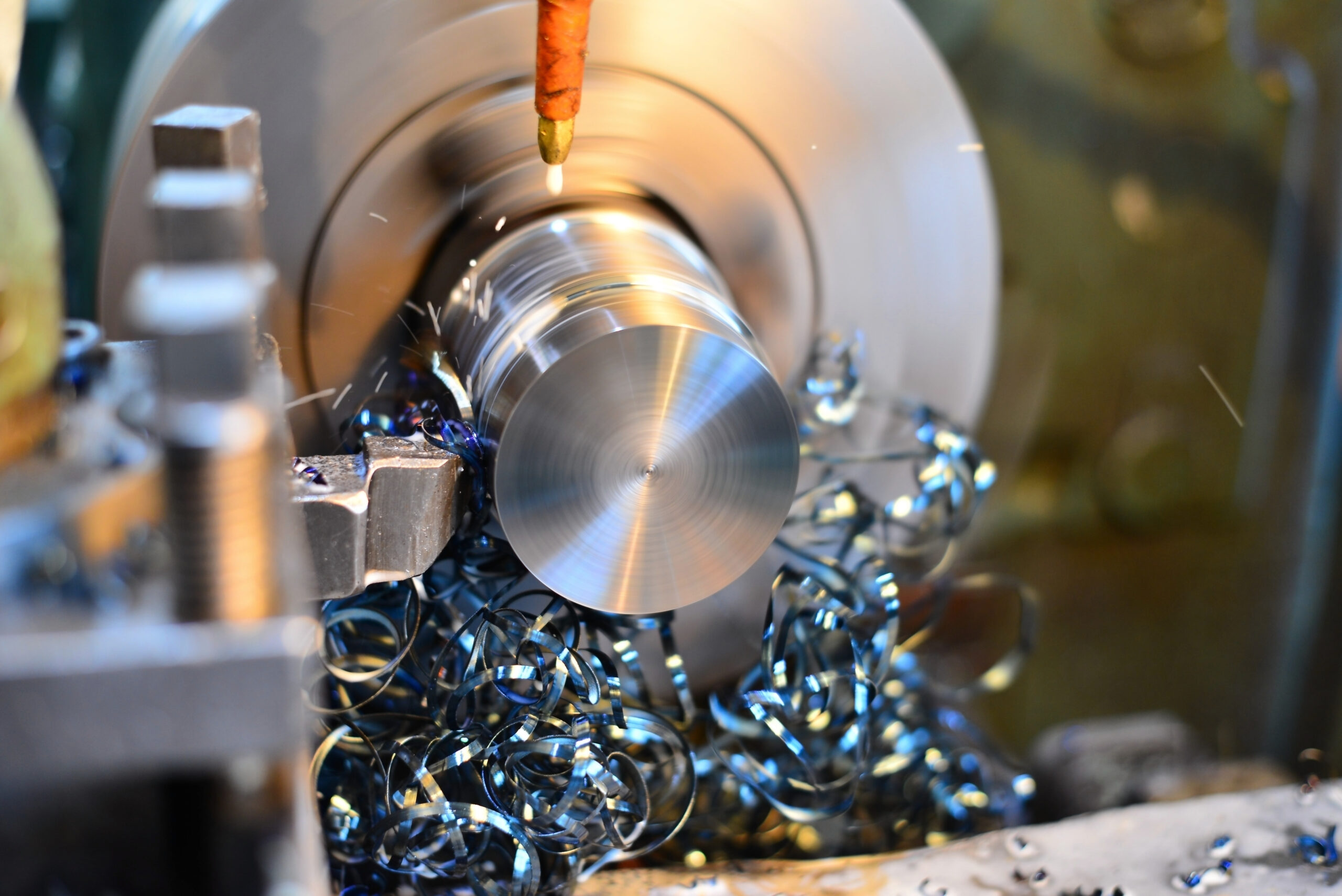

In: Kocurek MJ (ed) Pulp and paper manufacture, vol 5, 3rd edn. Non recycled paper is either landfilled or incinerated. Post-use, an increasing fraction of paper and paper products is recycled. In the paper factory, the pulp is dried and pressed to produce paper sheets. The pulp is then bleached and further processed, depending on the type and grade of paper that is to be produced. Pulp making can be done mechanically or chemically. The harvested wood is first processed so that the fibres are separated from the unusable fraction of the wood, the lignin. Paper production is basically a two-step process in which a fibrous raw material is first converted into pulp, and then the pulp is converted into paper. Paper for recycling accounts for about 50 % of the fibres used – but in a few cases straw, hemp, grass, cotton and other cellulose-bearing material can be used. The pulp for papermaking may be produced from virgin fibre by chemical or mechanical means or may be produced by the repulping of paper for recycling. Processing options and the type of wood processed are often determined by the final product. Pulp and paper mills are highly complex and integrate many different process areas including wood preparation, pulping, chemical recovery, bleaching, and papermaking to convert wood to the final product.

0 kommentar(er)

0 kommentar(er)